Why do lift failures occur so frequently in the summer heat? This is mainly due to the fact that the core components of the lift are generally located on the top floor of the house. The hot weather makes the temperature of the lift machine room rise, while the upper limit of the working environment temperature of the equipment can only be around 40 degrees, once the temperature control line is exceeded, the system will stop running by itself and the phenomenon of sudden stopping of the lift midway will occur. It affects the normal operation, for example, the lift suddenly stops and shuts down in normal operation, the lift does not open or close the door when running to the door area, the lift cannot change speed when running to the door area, etc.

Today, we will talk in detail about why the temperature of the machine room has such a great impact on the normal operation of the lift in summer. We hope that this article can draw the attention of the A-party to effectively cool down the machine room of the lift and ensure the normal operation of the lift together!

Causes of elevated machine room temperature

1. The location of the building structure of the machine room itself

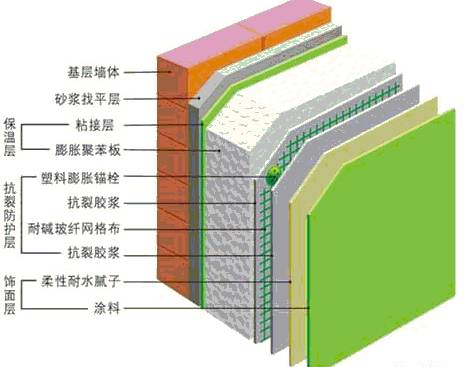

Most of the elevator rooms are on the roof level of the building, some of them are a raised dedicated room on the roof of the building, the roof and four walls of the room are the external envelope. The external envelope is also known as the external wall, and its temperature is closely linked to the greenhouse temperature, thus affecting the indoor temperature.

In hot summer weather, when the outdoor temperature is high, the temperature of the envelope is also high, which leads to an increase in the indoor temperature of the plant room. For a room, the greater the proportion of the entire maintenance structure accounted for by the external envelope, the greater the influence of the indoor temperature by the outdoor temperature, so the location of the server room determines that it is the room that is more affected by the ambient temperature and sun exposure in summer.

2. Heat emitted by the electrical system

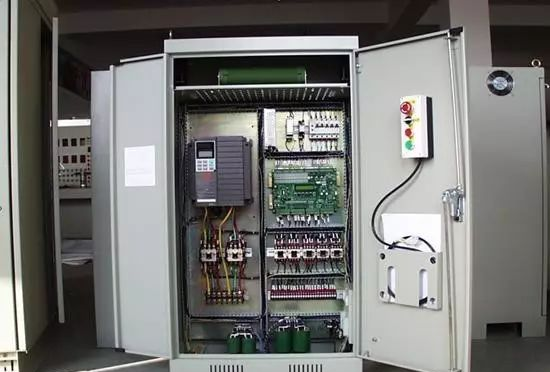

The main heat generating components of the electrical system in the machine room are the frequency converter, the braking resistor and the electric motor. The inverter and motor consume part of the electrical energy due to their own efficiency and release it in the form of heat; the braking resistor consumes the electrical energy generated by regenerating the lift and releases it in the form of heat. Both parts of the heat are emitted into the machine room causing the room temperature to rise.

(1) Inverter

The frequency converter consists of a main circuit and a control circuit. The main circuit is the power exchange part of the motor that provides voltage and frequency regulation power and consists of three parts: the rectifier, the smoothing circuit and the inverter. The inverter component of the inverter, the insulated gate bipolar transistor (IGBT), is the main source of heat generation in the inverter, and the heat generation of the IGBT is mainly concentrated at the moment of switching on and off. The heat generation of the IGBTs is mainly concentrated at the moment of switching on and off. The inverter for lifts needs to be started frequently, thus releasing a large amount of heat.

(2) Braking resistors

The braking resistor itself is the consumption of energy into heat, for example: when the lift is unloaded and moving up, the counterweight is heavier than the car, the rotor of the main machine rotates and cuts the movement of the stator coil magnetic force line, generating self-generation, so that the motor changes from electric state to power generation state, and this regenerative energy will pass through the braking unit of the inverter and eventually be consumed by the braking resistor as heat. In the work of a unit has done a test, two running the same frequency of the lift, one of the lift using external power as power, the lift regenerative power generation by the brake resistor consumed, the other lift using external power and power-saving feedback device for power, power-saving feedback device energy from the lift regenerative power generation, after running for a period of time, the external power consumption than the other power consumption less 35%. This shows how much heat is generated by the braking resistor, which is about 1/3 of the lift’s electrical energy consumption.

(3) Motor

The operation of the motor itself has a certain amount of electrical energy consumption. According to the motor heat formula Q=I²Rt, the heat released during the operation of the motor is proportional to the square of the current. The electric motor has the highest current in the process of starting and braking, and the lift, as a means of vertical transportation, has to start and brake frequently, which will generate a large amount of heat.

High temperature in the machine room on the lift

Effects on normal operation

1. Impact on the electrical control system

(1) High temperature is likely to cause abnormalities in the microcomputer control board program

The electronic devices on the microcomputer control board or PLC carry out logic control through voltage and current size comparison and respond to the execution of external instructions. Due to the material temperature characteristics of the electronic devices, at a temperature higher than that allowed, the logic judgment of the electronic devices will be wrong and the microcomputer control board will be unstable.

(2) High temperature easily damages electronic components

(a) Inverter

The failure rate of the inverter rises exponentially with the rise of temperature, and the service life decreases exponentially with the rise of temperature, and the service life of the inverter is halved when the ambient temperature rises by 10℃.

When the ambient temperature exceeds the permissible temperature, it will cause the parameters of the inverter in the inverter circuit to change in the opening time and closing time, resulting in the alternating process, one device is already on while the other is not ready to close, causing a “straight-through” between the upper and lower devices of the same bridge arm, which will put the part in an instantaneous The inverter is instantly damaged and the inverter cannot work normally. At the same time, the temperature of the inverter’s insulation performance will be greatly reduced, easily leading to damage to the inverter, resulting in lift failure.

(b) Braking resistor

When the ambient temperature is too high, it is easy to make the brake resistor dissipate heat for too long. If the lift runs frequently, the heat of the brake resistor accumulates many times, which eventually leads to damage due to high brake resistor temperature and even causes fire and other safety accidents.

(c) Other electronic components

Contactors, relays, transformers, these electronic components in the work, due to current through the conductor and coil and resistance losses; AC circuit due to the role of alternating electromagnetic, in the magnet to produce eddy current and hysteresis losses. All these losses are almost entirely transformed into heat energy, which is partly dissipated into the surrounding medium and partly retained in the appliance, causing the temperature of the appliance to rise. At this time, if the ambient temperature is too high, the electronic components are poor heat dissipation, one will make the reliability of electronic components greatly reduced; the second is to reduce the service life of electronic components, and even damage to electronic components. Statistics show that the temperature of electronic components every 2 ℃, reliability decreased by 10%, the temperature rise of 50 ℃ when the life of the temperature rise of 25 ℃ only 1/6.

2. The impact on the mechanical system

The mechanical system of the lift machine room is mainly the traction machine, which is usually composed of motor, brake, gearbox, traction wheel, guide wheel, frame, disc rider wheel, etc.

(1) Effect on the traction motor

When the ambient temperature exceeds the permissible temperature of the machine room, it will seriously affect the heat dissipation of the traction motor. Due to the frequent starting and braking of the motor, the motor itself will release a lot of heat, and the high temperature of the machine room cannot be eliminated in time.

Although the structural design of the motor is well thought out in terms of strengthening the heat dissipation of the stator iron core. For example, some products are designed to be supported by end caps, eliminating the need for a traditional machine base, making the core an open structure and enhancing the cooling effect; strengthening the arrangement of the ventilation channels around the stator and rotor cores; increasing the ventilation capacity of the wind shield holes, etc., but this structure is less used in motors. Most of them are equipped with cooling fans, controlled by thermal switches located on the surface of the stator core. When the core surface temperature reaches about 60°C, the thermal switch is activated and the fan is connected to the traction motor for forced ventilation and cooling. The cooling effect of forced cooling is not obvious in the case of high temperatures in the machine room. Considering that the motor temperature will continue to rise when forced cooling fails to cool down, some motor products have thermistors buried in each phase winding. When the motor temperature rises to 155°C, the resistance of the internal thermistor increases sharply and the thermal protection relay in the control circuit is activated, forcing the lift to change speed and stop at the nearest floor station to open the door until the motor cools down before restarting operation.

Although this method can play a role in protecting the motor, the long hours of hot weather in summer and the frequent stopping of the lift for protection seriously affect the normal operation and use of the lift.

(2) Impact on the gearbox

The gearbox is composed of worm wheel and worm gear. The worm gear is generally made of materials with high hardness and good rigidity, most of which are made of nickel-chromium alloy steel or silicon-manganese alloy steel, but also carbon steel forged with 0.4%-0.55% carbon content, and the surface of the worm must be hardened by quenching or carburizing. The worm wheel rim is made of phosphor bronze, tin bronze or copper-tin-nickel alloy with a low coefficient of friction by machining. As the coefficient of thermal expansion of various materials is different, and the coefficient of thermal expansion of the worm wheel is about 1/2 of the coefficient of thermal expansion of the worm, when the temperature of the machine room is higher than 40℃, the heat in the air and the heat generated by the rotation and friction of the parts in the gearbox, both together, the temperature in the gearbox will be higher, and the continuous high temperature will cause thermal expansion of the parts, thus destroying the accuracy of the production of the worm gear in the gearbox This will reduce the axial clearance of the turbine shaft and worm shaft, increase the meshing surface, increase the friction of the friction surface, accelerate wear and tear, and seriously affect the comfort of the lift, as well as produce strange noises and damage the worm gear (e.g. when riding the lift, you will hear a rumbling sound in the lift machine room, and there will be abnormal vibration in the car). At the same time, the continuous high temperature in the gearbox will also reduce the viscosity of the lubricant, which is not conducive to the generation of a lubricant film and will accelerate the oxidation of the lubricant, affecting the lubrication effect of the worm gear and increasing its wear.

How to control the temperature of the machine room

1. Building structure

Lift machine room to do maintenance structure insulation treatment, reduce the impact of outdoor temperature on indoor equipment in the summer hot weather, at the same time can not be because it is equipment room and ignore the maintenance structure of the insulation, reduce the thickness of the maintenance structure.

2. Install ventilation and cooling equipment

In the state of natural ventilation, the installation of ventilation equipment to meet the requirements of the temperature of the server room, it is necessary to install air conditioning. When installing ventilation equipment (e.g. exhaust fans), it should correspond to the ventilation openings in the server room (e.g. louvers), making the air convective, thus serving the purpose of improving the ambient temperature of the server room.

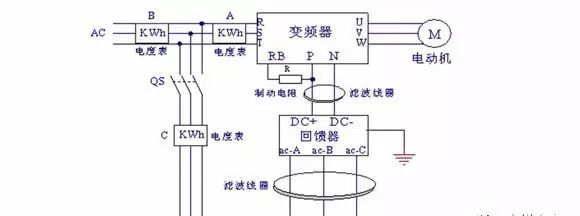

3. Use of energy saving devices

The heat energy of the braking resistor in the control cabinet is converted into electrical energy and stored in the battery or fed back into the power grid, which can eliminate the source of heat generation and also play an energy-saving role. When the lift is running, the lift inevitably has a power generation process. When the lift is unloaded and moving up and down, the motor rotor is dragged by external forces or the load itself is maintained by the rotational inertia, which makes the actual speed of the motor greater than the synchronous speed of the inverter output, at this time the motor is in a power generation state, the electrical energy issued by the motor will be stored in the filter capacitor inside the inverter. If this power is not consumed, the DC bus voltage will rise rapidly and affect the normal operation of the inverter. The usual way to deal with this energy is to add a braking unit or braking resistor, which turns this energy into heat and wastes it. The energy saving device can replace the braking unit and the braking resistor, and can feed this energy back into the grid, achieving green, environmentally friendly and energy saving purposes.

The energy saving device is designed to automatically detect the DC bus voltage of the inverter and the grid voltage, and through the processor and inverter to reverse the DC voltage of the DC link in the inverter into the AC voltage of the same frequency and phase as the grid voltage, and connect it to the AC grid after multiple noise filtering links, so as to achieve the purpose of energy feeding back into the grid.

4. Use units and maintenance units should arrange dedicated personnel to strengthen management

Maintenance units should regularly check whether the cooling equipment is working properly and conduct regular and careful inspections of the operation of heat generating sources (such as frequency converters, braking resistors and motors). For using units with multiple lifts, they should alternate their operation in the hot summer weather to avoid using only one lift for the convenience of the ride or for other reasons, which increases the burden of running the lift in the hot weather. In addition, the using unit should equip each lift machine room with a fire extinguisher.

To sum up: the increasing degree of intelligence of the lift control system does not completely eliminate lift failures, and the trend of frequent failures due to the ageing of lifts in use year by year will not change. However, by discussing and analysing the building structure, electrical control system and mechanical system of the lift machine room, and taking targeted measures to effectively control each link, we can ensure that the temperature of the machine room of the lift is within the normal range in the hot weather in summer, and eventually eliminate or reduce various failures caused by high temperature, so as to ensure that the lift operates in a safe, stable and reliable environment and better serve the users.

Post time: Jul-13-2022

![富吉-[LOGO]-105](https://www.fujisj.com/uploads/a78ec670.png)